When embarking on a plumbing or construction project, one of the critical components to consider is the type of fittings that will be used. Schedule 80 PVC fittings are renowned for their durability and strength, making them an excellent choice for various applications, from industrial settings to residential plumbing. According to industry expert John Thompson, a renowned plumbing engineer, "Choosing the right fittings is essential for ensuring the longevity and integrity of your piping system." His insight emphasizes the importance of understanding the specific characteristics and advantages of schedule 80 PVC fittings.

These fittings are designed to withstand higher pressure and are thicker than their schedule 40 counterparts, which makes them suitable for high-demand environments where reliability is paramount. This article delves into the various aspects of schedule 80 PVC fittings, exploring their benefits, applications, and installation practices. Whether you are a seasoned plumber or a DIY enthusiast, gaining a comprehensive understanding of these fittings can significantly enhance the quality and performance of your project.

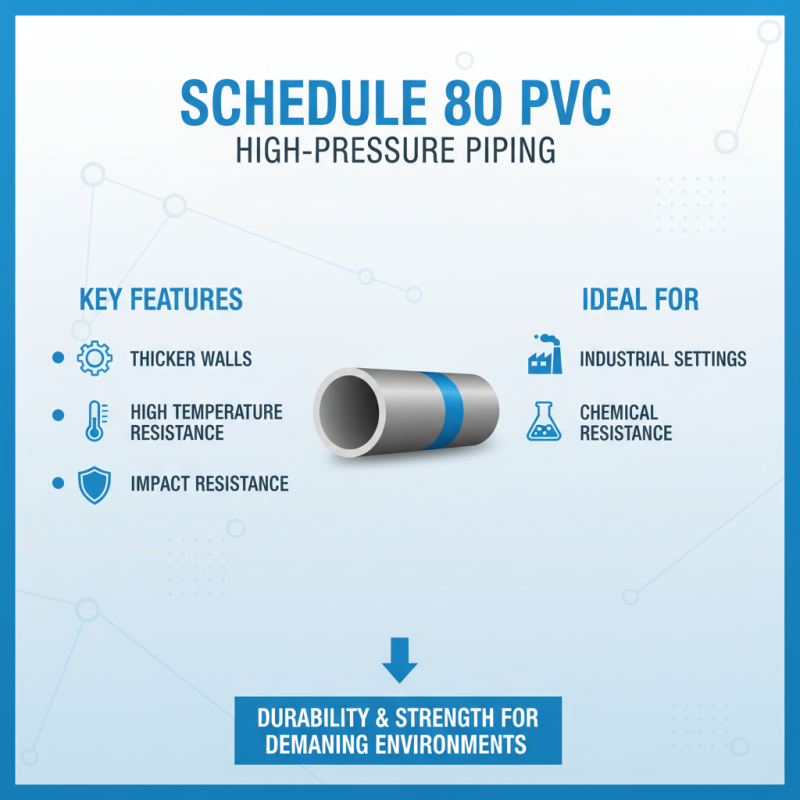

Schedule 80 PVC, or polyvinyl chloride, is a type of plastic piping that is designed for high pressure applications. It is thicker and more robust than Schedule 40 PVC, making it the ideal choice for projects that require increased durability and higher temperature resistance. The wall thickness of Schedule 80 PVC fittings provides enhanced strength and impact resistance, allowing them to withstand demanding environments. This is particularly crucial in industrial settings, where exposure to harsh chemicals and varying temperatures can compromise standard piping materials.

One of the key features of Schedule 80 PVC is its versatility. It can be used in various applications, including water treatment, chemical processing, and drainage systems. These fittings are not only resistant to corrosion and chemical reactions but also lightweight, allowing for easier handling and installation. Additionally, Schedule 80 PVC is known for its low thermal conductivity, which minimizes heat loss in piping systems. This combination of attributes makes Schedule 80 PVC fittings a dependable choice for both residential and commercial projects, ensuring longevity and reliability in piping systems across different industries.

Schedule 80 PVC fittings are becoming increasingly popular in various construction and plumbing projects due to their superior strength and durability. One primary benefit of using these fittings is their ability to withstand higher pressures compared to Schedule 40 counterparts. This makes them ideal for applications involving water or chemical transport, ensuring that systems can operate efficiently without the risk of leaks or failures. Their thicker walls provide not only enhanced pressure tolerance but also increased resistance to impact and environmental stressors.

Another advantage of Schedule 80 PVC fittings is their versatility and ease of installation. They can be used in a wide range of applications, from residential plumbing to industrial piping systems. The lightweight nature of PVC allows for manageable handling and installation, reducing labor costs and facilitating quicker project completion. Moreover, these fittings are corrosion-resistant and do not rust or degrade over time, making them a reliable choice for long-term use. With their excellent chemical resistance, they can efficiently transport corrosive substances, ensuring safety and integrity in various environments.

Schedule 80 PVC fittings are widely used in various applications due to their superior strength and durability compared to other types of PVC fittings. These fittings are designed to handle higher pressure and are ideal for applications that require robust piping solutions. Commonly found in industrial settings, Schedule 80 PVC fittings are used for water treatment facilities, chemical processing systems, and aquaculture operations where reliability is paramount.

In addition to industrial applications, Schedule 80 PVC fittings are also suitable for residential and commercial plumbing projects. They are often employed in systems designed for drainage, irrigation, and ventilation. The increased wall thickness of these fittings ensures they can withstand wear and tear from the elements, making them a preferred choice for both indoor and outdoor installations. Additionally, their resistance to corrosion makes them particularly effective in environments where exposure to harsh chemicals is a concern, allowing for longevity and consistent performance in various plumbing infrastructures.

When it comes to selecting Schedule 80 PVC fittings for your next project, understanding the specific demands of your application is crucial. Schedule 80 PVC is known for its thicker walls compared to Schedule 40, making it suitable for high-pressure applications. According to the Plastics Industry Association, Schedule 80 PVC can handle pressures up to exerting 280 psi at 73°F, which is significantly higher than its Schedule 40 counterpart. This strength makes it ideal for industries such as chemical processing, marine, and industrial applications where durability and reliability are paramount.

When choosing the right fittings, consider the environmental conditions they will face. Factors such as temperature, pressure, and exposure to chemicals can greatly impact the performance and longevity of PVC fittings. The American Society for Testing and Materials (ASTM) standards indicate that Schedule 80 PVC can withstand temperatures up to 140°F for continuous use, with short periods at even higher temperatures. Additionally, ensuring the fittings comply with ASTM D2467 specifications will provide assurance that you are using products designed to withstand rigorous conditions. By aligning the specifications of Schedule 80 PVC fittings with your project needs, you can ensure a robust and effective plumbing system that meets industry standards.

| Fitting Type | Nominal Size (inches) | Connection Type | Material | Pressure Rating (psi) | Typical Applications |

|---|---|---|---|---|---|

| 90-Degree Elbow | 1 | Socket | PVC | SDR 26 | Drainage, Waste, Vent (DWV) |

| Tee | 2 | Socket | PVC | SDR 26 | Fluid distribution and mixing |

| Straight Connector | 3 | Socket | PVC | SDR 26 | Piping extensions |

| Cap | 4 | Socket | PVC | SDR 26 | End closure of pipes |

| Union | 1.5 | Socket | PVC | SDR 26 | Connect and disconnect piping |

When working with Schedule 80 PVC fittings, proper installation is crucial to ensure a reliable and leak-free system. One of the first tips is to always ensure your work area is clean and free of debris. Dirt and dust can interfere with the sealing surfaces, potentially leading to leaks. Additionally, use the proper tools for cutting the PVC pipes to avoid jagged edges that may compromise the integrity of the fitting.

Another essential tip is to apply primer and cement properly. When using solvent cement, it’s vital to first apply a liberal amount of PVC primer to both the fitting and the pipe. This prepares the surfaces for bonding. Once the primer has dried, apply the solvent cement evenly and quickly, then assemble the fitting with a twist to ensure an even distribution before the cement sets. Remember to hold the connection in place for at least 30 seconds to allow it to set properly.

Lastly, allow ample cure time before putting the system under pressure. Each fitting and cement may have specific cure times, so be sure to consult the instructions. Leaving the installation undisturbed for the recommended duration will ensure that the bonds are strong, contributing to the long-term success of your plumbing project.

Sign up for our mailing list to stay informed and up to date with our latest news and products!

(905) 832 – 0600

2175-A Teston Road

Maple, Ontario

L6A 1T3

(780) 451 – 0238

24790 – 117 Avenue

Acheson, Alberta

T7X 6C2

(604) 882 – 1564

9511 – 194A Street

Surrey, British Columbia

V4N 4G4

(306) 955 – 6005

3926 Arthur Rose Avenue Saskatoon, Saskatchewan

S7P 0C9

(450) 687 – 2721

2750 Rue Bernard-Lefebvre

Laval, Quebec

H7C 0A5