Choosing the right PVC connectors can significantly impact the success of your projects. These connectors play a crucial role in ensuring a strong, reliable connection between pipes. With so many options available, making an informed choice can be overwhelming.

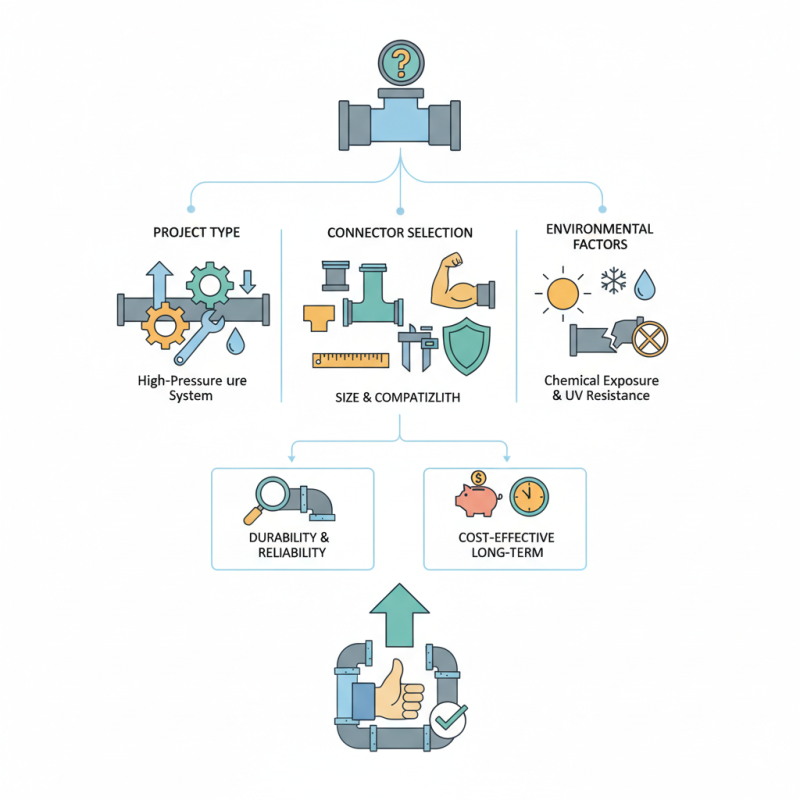

When selecting PVC connectors, consider the specific requirements of your project. Are you working with high-pressure systems or simply need a durable connection? Each application demands different types of connectors. Pay attention to the size, compatibility, and material strength of the connectors you choose.

It’s easy to overlook important details. For instance, a connector that seems perfect may not withstand certain environmental conditions. This could lead to costly repairs or replacements. Reflect on your past experiences with PVC connectors. Did you choose based on price rather than quality? Remember, investing in the right components now can save time and headaches later.

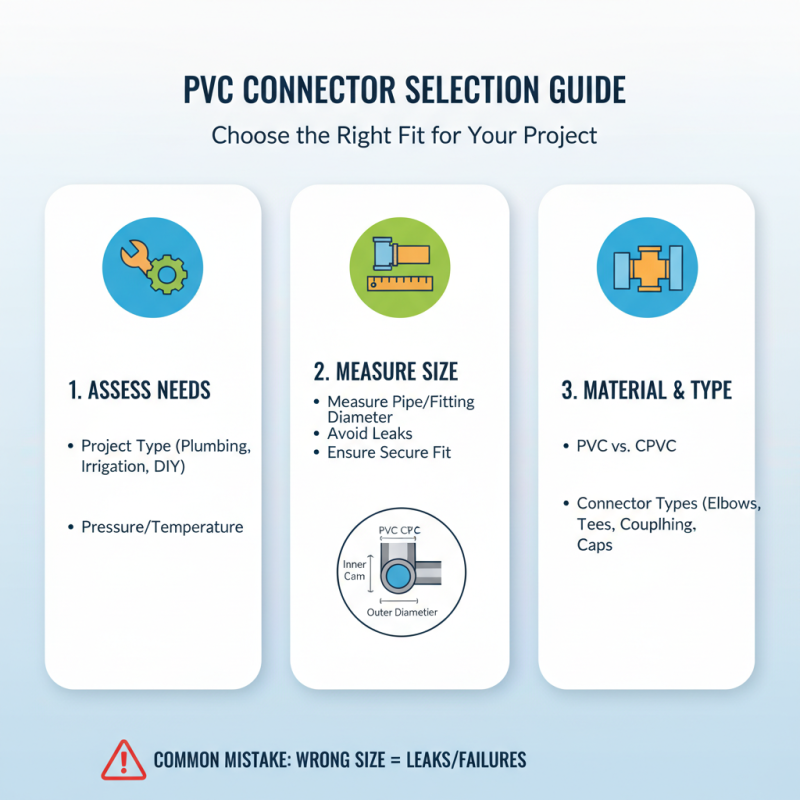

When working with PVC, understanding the different types of connectors is crucial. PVC connectors come in various shapes and sizes, each serving a unique purpose. For example, tees are ideal for branching off a main line. Couplings are perfect for connecting two pipes end to end. Elbows allow for directional changes. Each type has specific applications, and choosing the right one can make all the difference in your project.

In addition to basic shapes, connectors also vary by size and material. Some connectors are designed for pressure applications while others may not withstand high stress. Checking the specifications is essential. Some projects may require connectors with special features, like sealing rings for leak prevention. It's important to think about the environment where you will use these connectors. Heat, moisture, and UV exposure can impact performance.

Take time to evaluate your needs. If you're unsure which type to choose, consult with peers or seek advice from professionals. Don't rush your decision. It's easy to overlook details. However, the right choice will ensure your project’s longevity. Avoid frustration by researching thoroughly. Each connector has its role, and understanding this can save time and resources.

When selecting the right PVC connectors for your projects, it's vital to assess your project's specific needs. Size is a crucial factor. You need to measure the diameter of pipes or fittings you are working with. A common mistake is choosing connectors that are too large or too small. This can lead to leaks or fitting issues.

Pressure and temperature requirements also play important roles. Consider the working environment for your project. Will the connectors face high pressure or extreme heat? PVC connectors have limits that must be respected. Using them beyond their rated capacity can result in failure.

Many people overlook these factors. They may assume that all connectors will work universally. But that’s not the case. Each project is unique. Proper assessment can save time and resources in the long run. If unsure, consult with a knowledgeable source for guidance.

When evaluating PVC connectors, it is essential to consider material compatibility. PVC, known for its durability, is often used in plumbing and electrical applications. However, its performance can vary when paired with other materials. A report by the Plastics Industry Association notes that PVC is resistant to a variety of chemicals, which makes it suitable for diverse projects. Yet, it is vital to assess if the other materials used will react negatively with PVC.

For instance, metals such as copper and aluminum can cause galvanic corrosion when in contact with PVC. This can weaken the integrity of the connection over time. Studies show that approximately 30% of plumbing failures occur due to improper material selection. Choosing the wrong material can lead to leaks or reduced efficiency.

In contrast, using compatible materials like CPVC or polyethylene can enhance project longevity. These alternatives offer similar performance without the risks associated with metal interactions. A project manager's guide indicates that 40% of cost overruns stem from material compatibility issues. This statistic highlights the importance of thorough evaluation before making a final decision.

| Connector Material | Tensile Strength (MPa) | Temperature Resistance (°C) | Chemical Resistance | Cost (per unit) |

|---|---|---|---|---|

| PVC | 40 | 60 | Moderate | $0.50 |

| CPVC | 55 | 90 | High | $0.80 |

| PP (Polypropylene) | 30 | 100 | Very High | $0.60 |

| PPS (Polyphenylene Sulfide) | 70 | 250 | Extremely High | $2.00 |

| Stainless Steel | 520 | 400 | Excellent | $5.00 |

When installing PVC connectors, proper fitting is essential for a successful project. According to a recent industry report, over 30% of plumbing issues stem from improper installation of connectors. Ensure the connectors meet your project specifications. Measure pipes accurately. A small gap can lead to leaks or weak joints.

Preparation is key. Always clean pipe ends before fitting connectors. Dirt or debris can compromise the seal. In a study of DIY installations, over 40% of users failed to clean their materials. This common mistake led to significant rework. Use a primer where necessary. It enhances adhesion and further secures the fit.

For a neat installation, consider the alignment of your connectors. Misaligned joints can create stress points, leading to failure. Many professionals recommend a slight twist or turn during installation. This ensures a tighter fit and better durability. However, be cautious—over-tightening can crack PVC. Be aware, as this delicate balance is crucial for long-term success.

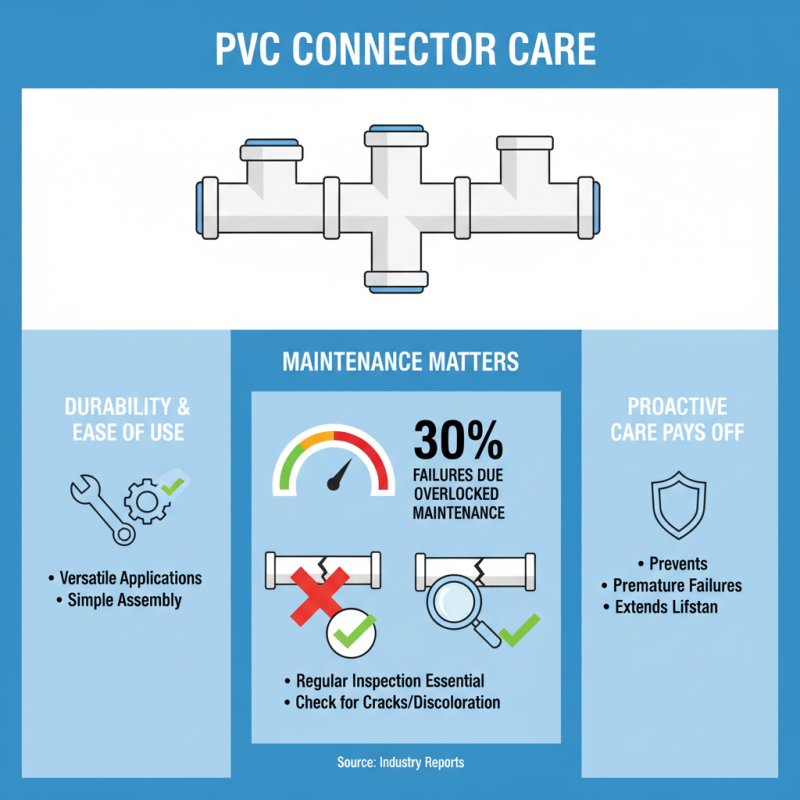

PVC connectors are popular in various applications due to their durability and ease of use. However, neglecting maintenance can lead to premature failures. Regular inspection is essential. Check for signs of wear, such as cracks or discoloration. According to industry reports, nearly 30% of failures occur due to overlooked maintenance. This statistic highlights the importance of proactive care.

Cleaning is another key factor. Dirty connectors can lead to poor performance and increased wear. Use a mild soap solution to remove debris. Rinse thoroughly to prevent corrosion. Statistics show that 15% of connector issues arise from inadequate cleaning practices. Keeping components free from grime enhances longevity.

It's crucial to store PVC connectors properly when not in use. Exposure to UV light and extreme temperatures can degrade materials over time. Use opaque containers to shield connectors from sunlight. Studies indicate that connectors stored correctly can last up to 40% longer. Failing to store them properly may lead to unexpected replacements down the line.

Sign up for our mailing list to stay informed and up to date with our latest news and products!

(905) 832 – 0600

2175-A Teston Road

Maple, Ontario

L6A 1T3

(780) 451 – 0238

24790 – 117 Avenue

Acheson, Alberta

T7X 6C2

(604) 882 – 1564

9511 – 194A Street

Surrey, British Columbia

V4N 4G4

(306) 955 – 6005

3926 Arthur Rose Avenue Saskatoon, Saskatchewan

S7P 0C9

(450) 687 – 2721

2750 Rue Bernard-Lefebvre

Laval, Quebec

H7C 0A5