Choosing the right PVC pipe connectors is crucial for any project. According to a recent report by the Pipe and Fittings Association, the global market for PVC connectors is projected to grow by 5% annually. These connectors are essential for ensuring the efficiency and durability of piping systems in various applications, from residential plumbing to industrial settings.

Expert Bob Johnson, a recognized specialist in the field, emphasizes, "The quality of PVC pipe connectors can greatly impact the longevity of your piping system." This insight reflects a broader consensus among industry professionals. Choosing inadequate connectors can lead to leaks or system failures, which can be costly.

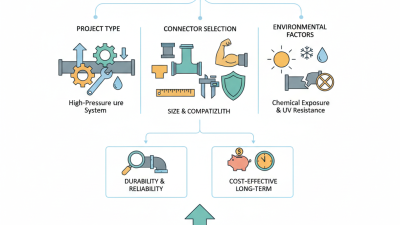

When selecting PVC pipe connectors, consider factors like size, pressure ratings, and compatibility with existing materials. A mismatch could result in significant project delays. Take the time to analyze available options, ensuring the connectors you choose meet the specific needs of your project. Remember, a poor choice today could have long-term consequences that are easily avoidable.

When choosing PVC pipe connectors, understanding their types and applications is crucial. PVC connectors are vital for creating strong, reliable plumbing systems. The main types include elbows, tees, couplings, and adapters. Each type serves a specific purpose. For instance, elbows change pipe direction, while tees allow for branching. Knowing these basics is essential for project success.

Data shows that over 70% of construction projects utilize PVC materials. This statistic highlights the importance of selecting the right connectors. Poor choices can lead to leaks or failures. Inadequate connectors may also lead to costly repairs and project delays. It's essential to consider the project's requirements, including pressure ratings and compatibility with existing systems.

Moreover, not all connectors are designed equally. Some may degrade faster under certain conditions. For example, UV exposure can weaken standard PVC over time. Understanding the application environment is key. In areas with high sunlight, using UV-resistant connectors can extend lifespan. Always evaluate the specific needs before making a decision. The right choice can enhance durability and efficiency in the long run.

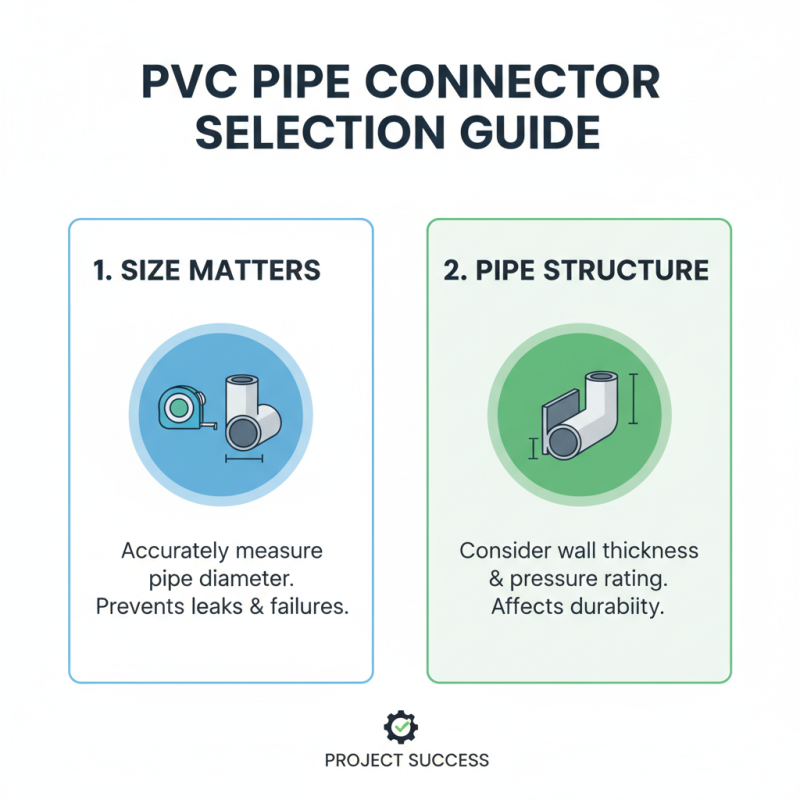

Choosing the right PVC pipe connectors greatly impacts your project's success. Several factors must be considered during selection. First, size matters. Measure the diameter of your pipes accurately. An incorrect size leads to leaks or system failures. Additionally, think about the schedule of your PVC pipes. Different schedules have varying wall thicknesses and pressure ratings, which affects durability.

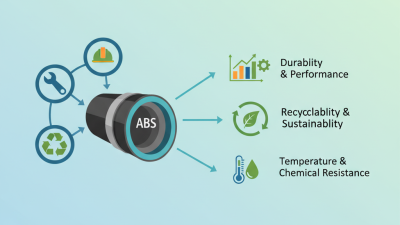

Material is another key consideration. PVC connectors come in various grades. Some are ideal for plumbing, while others suit electrical applications. Ensure the connector matches your project's needs. Environmental factors also play a role. If the connector will face extreme temperatures or chemicals, it’s essential to select one that can withstand these conditions.

Installation methods can differ too. Some connectors require solvents, while others may be threaded or pushed on. Reflecting on your skills and available tools can guide your choice. Lastly, check for compatibility. Mixing different materials can lead to unexpected issues. Evaluating these elements ensures a smoother process and better long-term results.

Choosing the right PVC pipe connectors is crucial for the success of your plumbing or construction project. When it comes to connector sizes, matching them with the appropriate PVC pipe diameters is essential. A misfit can lead to leaks or weakened joints. Measure the diameter of your pipes accurately to ensure a snug fit. This prevents future complications that could arise from poor connections.

Consider the specific requirements of your project. Sometimes, you might find that the standard sizes do not meet your needs perfectly. Custom solutions can be costly and time-consuming. If you choose a connector that is slightly larger or smaller, adjustments may be necessary. Using rubber gaskets can help with minor discrepancies, but they are not always the ideal solution.

Think about the environment where the pipes will be installed. Temperature and humidity can affect the integrity of the materials. In some cases, PVC can expand or contract, changing how connectors fit. Regular checks will be beneficial. Don't overlook the importance of proper installation techniques, as a poorly installed connector can create issues down the line. Adaptability is key, especially when working on unique projects.

When selecting PVC pipe connectors, understanding pressure ratings and durability is crucial. Pressure ratings indicate how much stress a connector can handle. This varies between different types of connectors and applications. For instance, standard PVC connects typically support pressure up to 150 PSI. However, high-performance connectors can withstand up to 300 PSI. Consequently, knowing your project's requirements is essential.

Durability also plays a significant role. Quality PVC connectors resist corrosion, UV light, and extreme temperatures. Research by industry experts shows that high-grade PVC connectors can last up to 50 years under proper conditions. Yet, it’s vital to inspect connectors regularly for wear and tear. Small cracks can greatly reduce their lifespan.

Tips: Always review the manufacturer's specifications before purchase. Consider the specific environment – factors such as soil type and moisture impact durability. Also, test the connectors under real conditions when possible. Don't overlook the importance of regular maintenance. This can prevent unforeseen failures down the line. A small oversight can lead to significant project delays.

| Connector Type | Pressure Rating (PSI) | Material Durability (Years) | Applications |

|---|---|---|---|

| Socket Connector | 150 | 10-15 | Residential plumbing, irrigation |

| Threaded Connector | 200 | 10-20 | Commercial systems, industrial applications |

| Elbow Connector | 150 | 10-15 | Turn corners in piping systems |

| Tee Connector | 150 | 10-15 | Branch off main lines |

| Cap Connector | 150 | 10-15 | Seal the end of pipes |

When installing PVC pipe connectors, safety is paramount. Begin by wearing appropriate protective gear, such as gloves and goggles. These items can prevent injuries from sharp edges and PVC dust. Always work in a well-ventilated space. Fumes from adhesives can be harmful if inhaled.

Ensure that connections are thoroughly cleaned before assembly. Dirt or debris can cause leaks. Use a clean rag to wipe the ends of each pipe and connector. Primer and cement should be applied quickly and evenly. Be cautious, as applying too much adhesive can lead to a mess. On the flip side, using too little might result in weak joints.

Finally, allow ample time for the adhesive to cure. Rushing this process can lead to failures down the line. It's wise to double-check your connections for any gaps or excess glue. These details matter in DIY projects. Reflect on your process, and learn from any mistakes. Each step is essential for a successful installation.

Sign up for our mailing list to stay informed and up to date with our latest news and products!

(905) 832 – 0600

2175-A Teston Road

Maple, Ontario

L6A 1T3

(780) 451 – 0238

24790 – 117 Avenue

Acheson, Alberta

T7X 6C2

(604) 882 – 1564

9511 – 194A Street

Surrey, British Columbia

V4N 4G4

(306) 955 – 6005

3926 Arthur Rose Avenue Saskatoon, Saskatchewan

S7P 0C9

(450) 687 – 2721

2750 Rue Bernard-Lefebvre

Laval, Quebec

H7C 0A5