Choosing the right PVC pipe fittings for your project can be challenging. With so many options available, it's easy to feel overwhelmed. These fittings are essential for ensuring proper flow and connection in plumbing systems. The right choice can make or break your project's success.

When selecting PVC pipe fittings, consider the specific requirements of your project. Think about factors like size, pressure rating, and compatibility. For example, a simple mistake in sizing can lead to leaks or pressure issues. It's crucial to pay attention to detail and not rush this process.

Remember that not all fittings are of the same quality. Some may appear more affordable but could cause future problems. Reflect on your needs and the potential long-term implications of your choices. Your final selection should not only meet immediate requirements but also offer reliability for years to come.

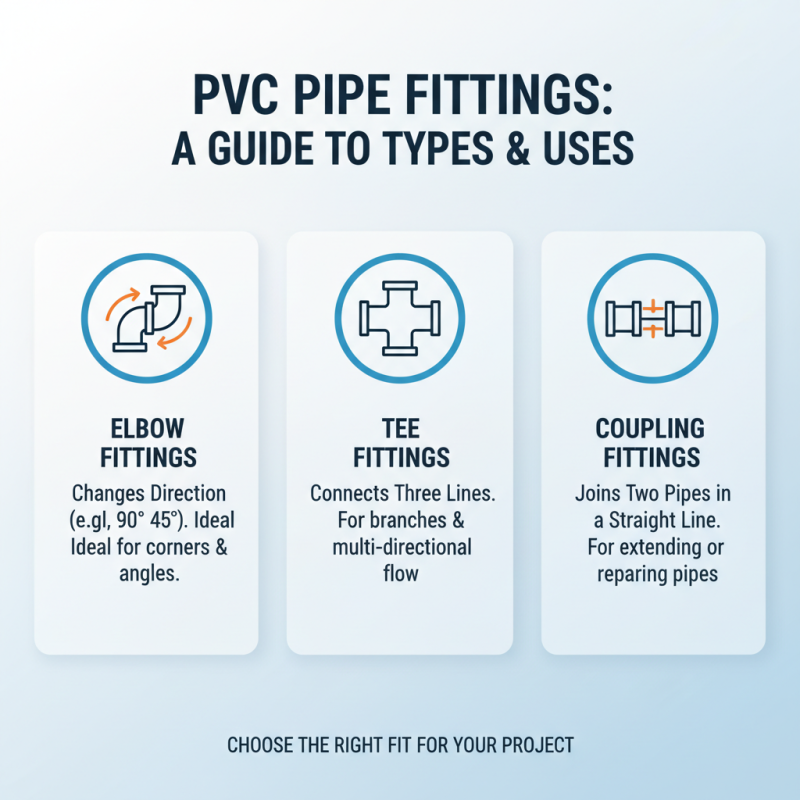

When selecting PVC pipe fittings, it's crucial to understand the various types available. PVC fittings come in many shapes and sizes, tailored for specific applications. There are elbow fittings, which allow for directional changes in pipes. Tees provide a way to connect three lines, while couplings join two pipes together. Each type serves a unique purpose and should align with your project’s requirements.

Consider the size and schedule of your pipes. Fittings vary in dimensions, and choosing the right size ensures a proper fit. Schedule 40 and Schedule 80 are common options, with Schedule 80 being thicker and more durable. Not all projects require heavy-duty fittings; the lighter ones may suffice for indoor use. Be wary of this, as improper selection can lead to leaks and failures down the line.

Also, remember that PVC can be used in various environments. Some fittings are designed for specific temperatures or chemical exposure. Take time to think about the conditions of your project site. Environmental factors can impact the longevity of your fittings. Reflecting on these details will help in making an informed choice that fits your needs.

Choosing the right PVC pipe fittings starts with understanding your specific project needs. Consider the type of fluid your system will carry. Different applications require varying levels of pressure tolerance and compatibility. For instance, potable water systems need fittings suitable for drinking water, while industrial applications may demand more durable options. Pay attention to the temperature range, too; not all PVC fits high heat conditions.

Another important factor is the size and compatibility with existing pipes. Measure the diameter and ensure a proper fit. Mismatched sizes can lead to leaks or breakage. Don't forget to evaluate the installation process. Some fittings are easier to work with than others, impacting your project's timeline. Also, think about the environment where they will be used. Exposure to UV rays or extreme weather can affect fitting longevity. Remember, each choice might have its drawbacks, like cost versus quality. Reflect on what matters most for your build.

When selecting PVC pipe fittings, compatibility is crucial. Different sizes and types of pipes can alter the overall performance of your plumbing system. Ensure the fittings match the pipe diameter. This is essential to avoid leaks. For instance, a fitting designed for a 2-inch pipe won’t fit properly on a 1.5-inch pipe. This mismatch can lead to frustrating issues down the line.

Consider the type of PVC you are using as well. There are various grades, such as schedule 40 and schedule 80, each with different wall thicknesses. Using the wrong fitting could compromise the system's pressure tolerance. Take note of the fitting's design and configuration. Some require solvent cement, while others aim for a simple slip-on connection. Misjudging these details can lead to installation dilemmas, which may require rework.

It's also essential to look at the system's purpose. Water pressure and temperature can affect fitting performance. A fitting that performs well in cold water may not handle hot water scenarios effectively. Think about these factors carefully. A slight oversight here could lead to costly repairs later. Compatibility goes beyond mere measurements; it requires a thoughtful assessment of the entire project scope.

When choosing PVC pipe fittings, quality and durability are crucial. These fittings must endure pressure, temperature changes, and exposure to elements. Inspect the fittings for any visible imperfections. Cracks, discoloration, or warping can indicate poor quality. A closer look often reveals hidden issues.

Consider the material specifications. Not all PVC is created equal. Look for fittings that meet industry standards. Certifications can offer assurance of reliability. However, even well-rated products can fail under certain conditions. Evaluate your specific project requirements carefully.

Remember, the installation process affects durability too. Improper installation can lead to leaks or breakages. Utilize proper techniques and tools for a secure fit. Reflect on your past experiences. Learning from previous mistakes can guide better choices for future projects. Each detail matters in ensuring a successful outcome.

When working with PVC pipe fittings, proper installation is crucial for long-lasting results. According to industry reports, about 60% of pipe failures are due to improper installation. This statistic highlights the importance of getting it right. Ensure all fittings are clean before joining them. Any dirt or debris can lead to weak connections.

One essential tip is to apply the appropriate primer. Many installers skip this step, thinking glue alone is sufficient. The right primer prepares the pipe surface for better adhesion. In turn, this can prevent leaks, saving you from costly repairs. Use a uniform coating of primer and allow it to dry briefly before applying the cement.

It's important to allow the fittings to set properly. Rushing this process can lead to misalignment and leaks. A common mistake is touching or moving the pipes before they are fully cured. The curing process may take up to 24 hours, depending on the environment’s temperature and humidity levels. Patience during this phase pays off in the long run.

Sign up for our mailing list to stay informed and up to date with our latest news and products!

(905) 832 – 0600

2175-A Teston Road

Maple, Ontario

L6A 1T3

(780) 451 – 0238

24790 – 117 Avenue

Acheson, Alberta

T7X 6C2

(604) 882 – 1564

9511 – 194A Street

Surrey, British Columbia

V4N 4G4

(306) 955 – 6005

3926 Arthur Rose Avenue Saskatoon, Saskatchewan

S7P 0C9

(450) 687 – 2721

2750 Rue Bernard-Lefebvre

Laval, Quebec

H7C 0A5