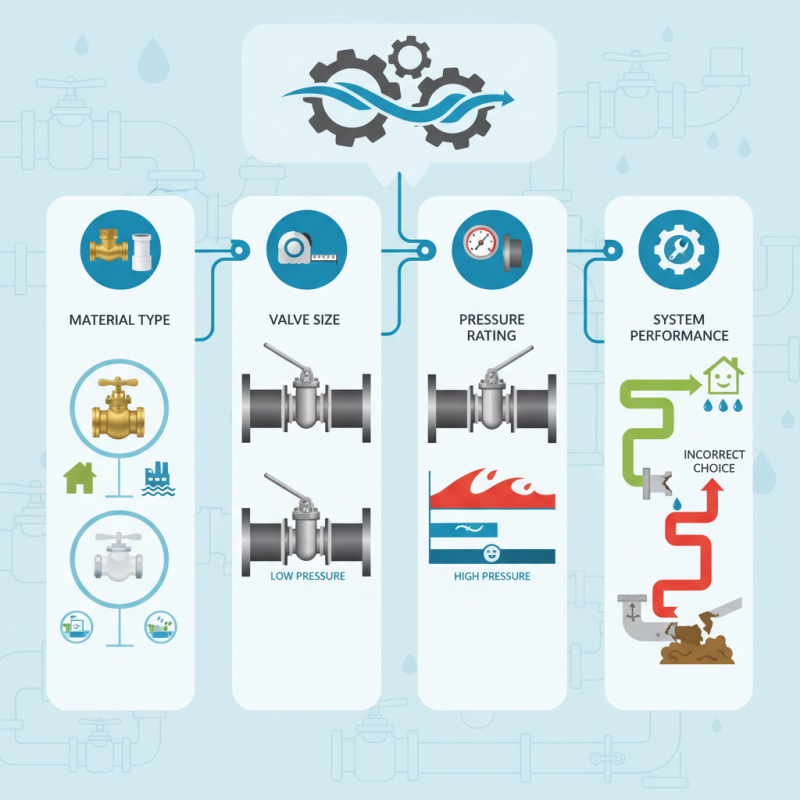

Choosing the right swing check valve for plumbing needs can seem daunting. These valves are essential for preventing backflow in piping systems. When selecting one, it’s crucial to consider several factors.

The type of material matters. For example, brass, stainless steel, or PVC options exist. Each has unique benefits for specific applications. Additionally, the size of the swing check valve must match the existing pipes. Incorrect sizing can lead to leaks or inefficient operation.

It's also vital to assess the pressure ratings. Not all swing check valves handle high pressure effectively. Careful consideration of these elements will ensure better system performance. Mistakes in selection can cause operational issues, leading to costly repairs. Thus, thorough reflection on your choices is necessary for optimal results.

Swing check valves play a crucial role in plumbing systems. They ensure that fluid flows in one direction only. This prevents backflow, protecting your system from potential damage. There are different types available, tailored for specific applications.

One common type is the vertical lift swing check valve. It’s great for high-pressure systems. These valves open fully, allowing maximum flow. However, they may require more space. Another variant is the horizontal swing check valve. This type is useful in lower-pressure systems. They can be compact, making them easier to install.

You might also encounter spring-loaded swing check valves. These have a spring that helps close the valve more quickly. They are ideal for fast-changing flow rates. Yet, they can be more expensive and need regular maintenance. Choosing the right type requires careful thought about your needs and system capabilities. Always consider the environment where the valve will be installed.

Choosing the right swing check valve for your plumbing needs requires careful consideration. There are key factors to keep in mind.

First, think about the pipe size. The valve must fit perfectly to prevent leaks. Common sizes range from half an inch to several inches.

Next, consider the pressure ratings. Different valves are built to withstand varying levels of pressure. Make sure to match the valve's rating with your plumbing system. This ensures reliability and safety. For plumbing systems with fluctuating pressures, select a valve designed for those conditions.

Tips: Check the material of the valve. Common options include brass, PVC, and stainless steel. Each material affects durability and compatibility with fluids.

Another important aspect is the direction of flow. Swing check valves only allow flow in one direction. Ensure that your installation aligns with this requirement. An improper installation could lead to backflow issues. Always double-check the installation manual.

In some cases, the choice may not be straightforward. You might face options that seem equally good. Reflect on the specific needs of your plumbing system. Sometimes, a more expensive valve could save costs on repairs later. Consider longevity in your decision-making process.

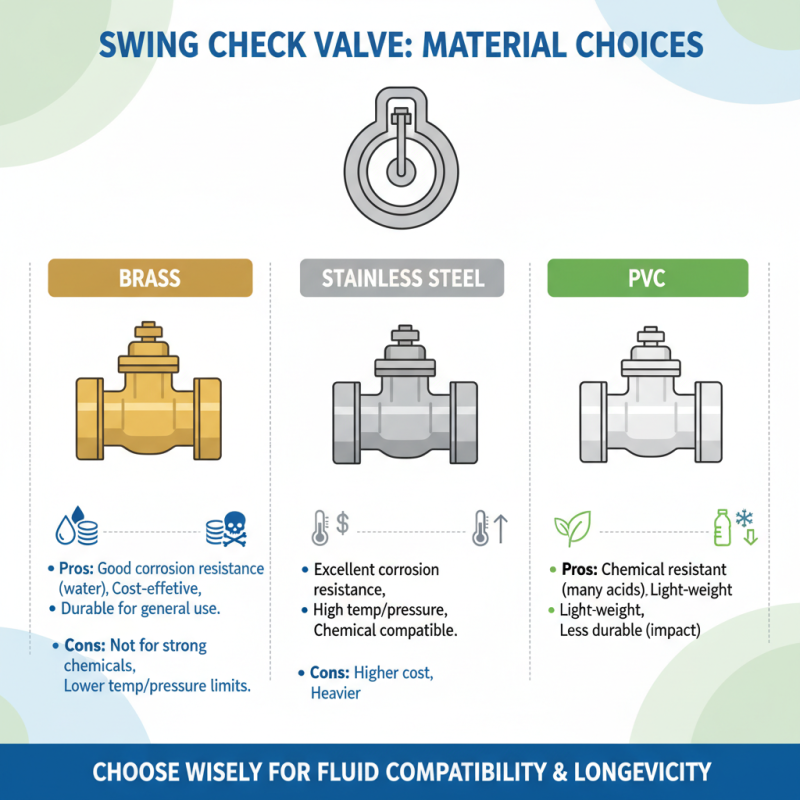

When selecting a swing check valve, understanding material choices is crucial. Different materials can impact durability and compatibility with various fluids. Common materials include brass, stainless steel, and PVC. Each type offers distinct advantages and disadvantages.

Brass valves are known for their strength and resistance to corrosion. They perform well in water and gas applications. However, they may not be suitable for aggressive chemicals. Stainless steel valves offer enhanced durability and resist oxidation. Despite being more expensive, they perform well in high-pressure environments. PVC valves are lightweight and resistant to acids, making them ideal for certain applications. Nonetheless, they may not handle high temperatures effectively.

Tips: Always consider the fluid's characteristics when choosing a valve. Assess temperature, pressure, and chemical compatibility. A mismatched valve can lead to leaks or failures.

It’s essential to evaluate the installation environment. For instance, a valve exposed to extreme temperatures may require specialized materials. Additionally, some valves may not perform as expected in real-world conditions. Investigating user reviews or industry reports can provide valuable insight into long-term performance. Don't overlook the importance of reliable sourcing and manufacturer ratings.

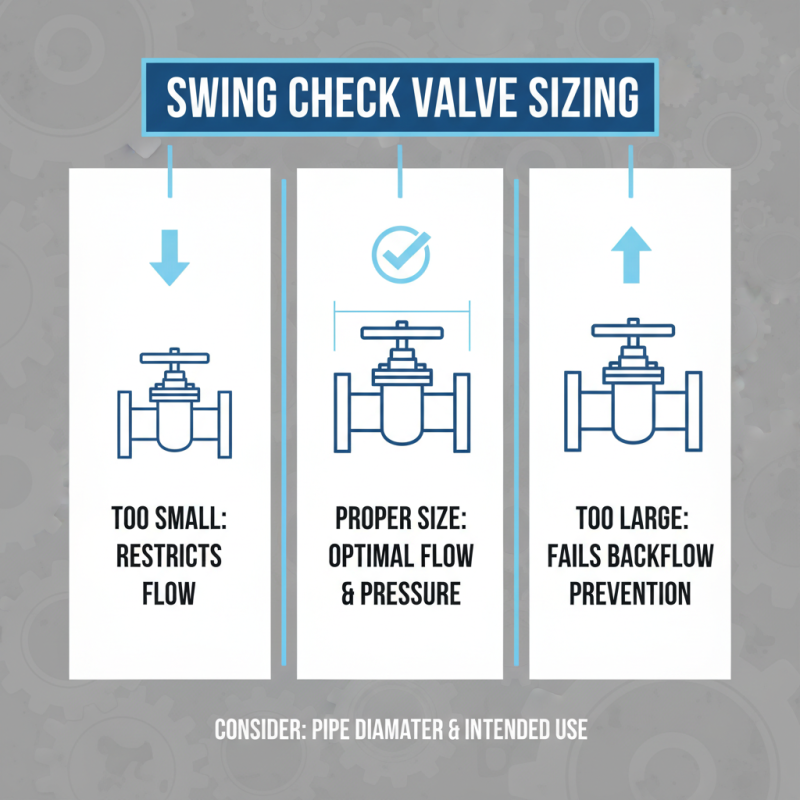

When selecting a swing check valve, sizing is crucial for effective performance. A properly sized valve ensures optimal flow rates and meets pressure requirements. It’s important to consider the pipe diameter and the intended use. A valve too small can restrict flow, while one too large may fail to prevent backflow.

Tips: Measure the existing pipe before buying. Use a flow rate calculator to determine the need. Always account for pressure fluctuations in your system.

Consider the materials as well. Plastics and metals can vary in durability. Ensure that the valve can withstand your plumbing conditions. A mismatch can lead to leaks or premature failure. Pay attention to installation space as well. A bulky valve might not fit where intended.

Remember, even minor errors can result in significant issues later. It may seem trivial, but small sizing mistakes complicate maintenance. Take your time to evaluate all these factors. In the end, seeking professional advice can save you time and money.

When installing a swing check valve, precision is key. Ensure the valve is oriented correctly. The flow direction should match the arrow on the valve body. Using pipe joint compound or Teflon tape can help create a tight seal. Avoid over-tightening; it may damage the valve.

After installation, regular maintenance is crucial for optimal performance. Check for any leaks around the valve regularly. Listen for unusual noises that might indicate problems. If the valve doesn't close properly, it could be time for a replacement.

Sometimes, a swing check valve may not function as expected. This might happen due to debris or sediment buildup. Clean the valve occasionally to prevent blockage. Don't rush through this process; take your time to inspect all components. Small issues can lead to larger problems down the line.

Sign up for our mailing list to stay informed and up to date with our latest news and products!

(905) 832 – 0600

2175-A Teston Road

Maple, Ontario

L6A 1T3

(780) 451 – 0238

24790 – 117 Avenue

Acheson, Alberta

T7X 6C2

(604) 882 – 1564

9511 – 194A Street

Surrey, British Columbia

V4N 4G4

(306) 955 – 6005

3926 Arthur Rose Avenue Saskatoon, Saskatchewan

S7P 0C9

(450) 687 – 2721

2750 Rue Bernard-Lefebvre

Laval, Quebec

H7C 0A5