Choosing the right swing check valve can be a challenging task. Expert engineer, John Smith, emphasizes, "Selecting the proper valve ensures system efficiency." Swing check valves are crucial for preventing backflow in piping systems. Understanding their function and design is essential for effective operation.

Many factors influence this decision. Flow rate, pressure, and material play significant roles. Incorrect choices can lead to system failures and costly repairs. Researching different options is critical. Testing out valves in your system helps identify the best fit.

Valves come in various sizes and designs. Each type serves different applications. Overlooking details could result in inefficiency. Understanding specifications and applications of swing check valves is vital. Don't rush the selection process; take the time to reflect on your needs and system requirements.

Swing check valves are essential components in various systems. They allow fluid to flow in one direction while preventing backflow. Understanding how these valves function is important for proper selection. They operate using a disc that swings open with the flow and closes when it reverses.

Attention to detail is crucial when choosing swing check valves. Consider the size and pressure rating of your system. Incorrect sizing can lead to inefficiencies. A valve that’s too large may not close properly, while a small one might fail under pressure. The material of the valve also matters. Different materials can withstand varying conditions.

Some may overlook installation angles. Installing a swing check valve horizontally may not always be ideal. It could lead to performance issues. Regular maintenance is often neglected as well. Without routine checks, wear and tear can become problematic. A swing check valve is a simple yet critical piece of equipment in any fluid system.

When selecting a swing check valve, there are several key factors to consider. First, the valve size must match your piping system. Measure the diameter of the pipe. This step is crucial. If the valve is too large or small, it won’t function properly. Also, consider the pressure ratings of your system. Ensure the valve can handle the pressure levels.

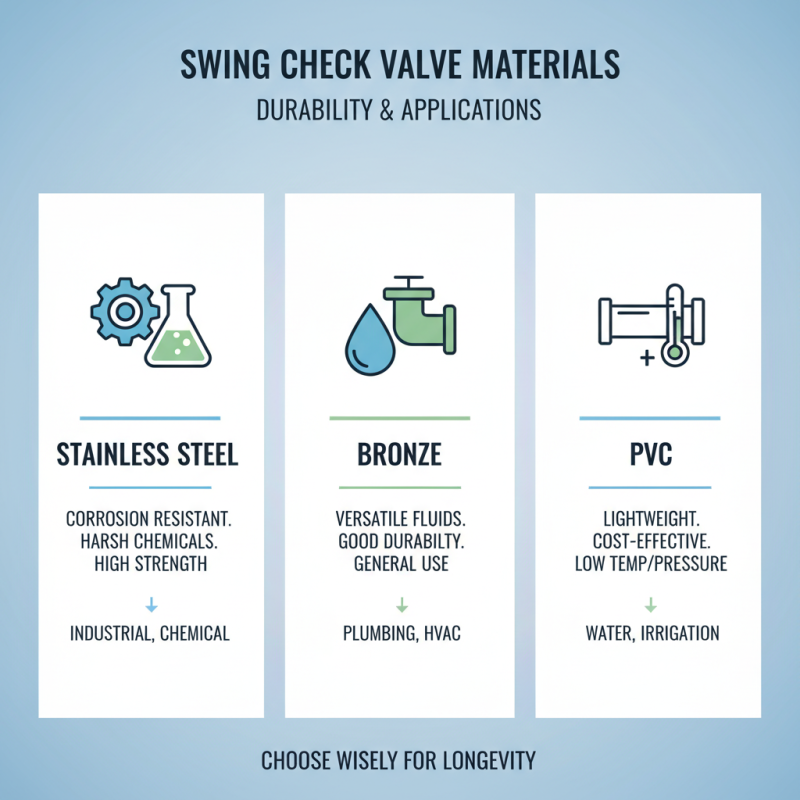

Material choice is another critical factor. Swing check valves come in different materials, such as stainless steel or plastic. The right material affects durability and resistance to corrosion. It’s essential to think about the fluid type. For example, a valve used for saltwater needs to resist corrosion better than one used for fresh water.

Tips: Always check your valve for balance. It helps prevent slamming, which can lead to leaks. If you're unsure, consult with a professional. Also, consider installation ease. Complicated setups are often problematic. Take your time to assess these factors carefully. Your choice of valve can significantly impact system performance.

When selecting a swing check valve, materials and durability play crucial roles. Many options exist. Common materials include stainless steel, bronze, and PVC. Each material has unique properties. For corrosive environments, stainless steel is often preferred. It withstands harsh chemicals well. Bronze can handle various fluids but may not last as long as steel. PVC is lightweight and cost-effective but may not handle high temperatures.

Tips: Evaluate your system's specific needs carefully. Consider fluid temperature and pressure. This assessment will inform your material choice. Look for valves with high durability ratings to minimize maintenance and replacements.

Don’t overlook installation and operational conditions. A durable valve can fail if not installed properly. Improper alignment or excessive vibrations can shorten a valve's lifespan. Regular inspections can help spot potential issues early. Just remember, the right mix of material and proper care can enhance reliability.

Choosing the right swing check valve requires careful consideration of sizing and flow rate. The valve must match the specifications of your system. If the valve is too small, it might restrict flow. Conversely, an oversized valve can lead to inefficiencies and turbulence. This mismatch can cause long-term damage to the system.

Flow rate is another critical factor. You need to know the maximum and minimum flow rates in your application. This ensures that the valve operates effectively under varying conditions. If you overlook this, it may lead to poor performance. Take the time to measure accurately. Underestimating these details can be costly.

Installation also plays a significant role. Ensure that the valve is positioned correctly in the pipeline. An improper angle can affect flow dynamics. Check the manufacturer’s guidelines for proper orientation. An easy mistake is neglecting regular maintenance checks. Ignoring this can lead to unexpected failures. Always be proactive in your approach.

| Dimension (mm) | Nominal Size (inches) | Flow Rate (m³/h) | Pressure Drop (bar) | Operating Temperature (°C) |

|---|---|---|---|---|

| 50 | 2" | 15 | 0.5 | 80 |

| 65 | 2.5" | 25 | 0.7 | 90 |

| 80 | 3" | 40 | 1.0 | 100 |

| 100 | 4" | 70 | 1.5 | 120 |

| 150 | 6" | 120 | 2.0 | 150 |

Swing check valves play a crucial role in various industries. Common applications include water supply systems, HVAC, and wastewater treatment. According to the Global Check Valves Market Report, the demand for these valves is projected to grow by 6.5% annually. This growth reflects their importance in fluid control.

In water supply systems, swing check valves prevent backflow. They ensure clean water is delivered without contamination. In HVAC systems, they help maintain pressure and efficiency. Wastewater treatment plants rely on these valves for effective operation. They are essential in managing flow direction and preventing system failures.

Tips: Always assess the fluid characteristics. Consider factors like temperature, pressure, and the fluid's composition. These elements are key to selecting the right valve. Use reliable materials that withstand corrosion. Some users overlook this and face unexpected failures later. Undoubtedly, swing check valves improve performance but need informed choices for optimal results.

Be cautious about installation. Improper alignment can lead to issues. Regular maintenance helps identify early signs of wear. Reflection on these practices can significantly enhance system longevity. Make decisions based on thorough evaluations.

Sign up for our mailing list to stay informed and up to date with our latest news and products!

(905) 832 – 0600

2175-A Teston Road

Maple, Ontario

L6A 1T3

(780) 451 – 0238

24790 – 117 Avenue

Acheson, Alberta

T7X 6C2

(604) 882 – 1564

9511 – 194A Street

Surrey, British Columbia

V4N 4G4

(306) 955 – 6005

3926 Arthur Rose Avenue Saskatoon, Saskatchewan

S7P 0C9

(450) 687 – 2721

2750 Rue Bernard-Lefebvre

Laval, Quebec

H7C 0A5