When it comes to selecting plastic pipe fittings, making informed choices is crucial. Expert Dave Johnson, a veteran in the plumbing industry, says, "Choosing the right fittings can save time and money in the long run." His insight underscores the significance of understanding your project needs before making a purchase.

Plastic pipe fittings come in various shapes and sizes, often leading to confusion. It’s essential to evaluate the specific requirements of your plumbing system. Look for durable materials that can withstand pressure and temperature changes. However, not all products are equal, and sometimes the cheaper options may not last.

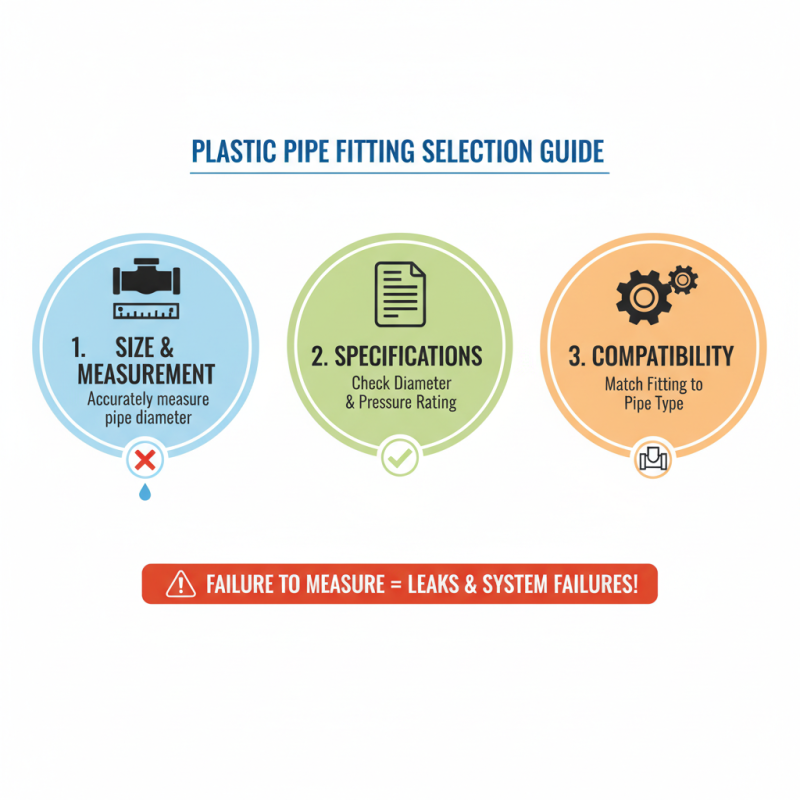

Many overlook the importance of size and compatibility when selecting plastic pipe fittings. A poor fit can lead to leaks or even significant damage. If you’re unsure, consult a professional or conduct thorough research. Reflecting on past mistakes can help in avoiding costly errors. Always weigh your options carefully before deciding.

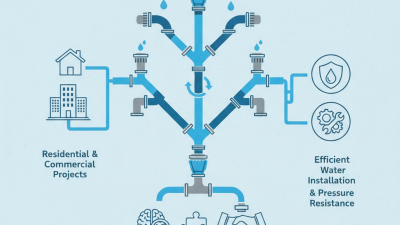

When selecting plastic pipe fittings, it's crucial to understand the types available. There are several common varieties, including PVC, CPVC, and ABS. Each type offers unique characteristics suited to specific applications. For instance, PVC is widely used due to its corrosion resistance and affordability. According to a study by the Plastic Pipe and Fittings Association, PVC accounts for over 75% of the plastic fittings market.

Tips: Always assess the intended use of your fittings before purchasing. Consider factors such as pressure ratings and temperature limitations. Not all plastics perform equally under stress.

CPVC, on the other hand, is suitable for hot water applications due to its higher temperature tolerance. However, it’s essential to note that not all CPVC fittings can withstand high levels of chlorine. Potential users should be mindful of potential chemical interactions. Industry reports emphasize the importance of detailed specifications to avoid failures.

Tips: Verify compatibility with existing systems. It’s easy to overlook this aspect. Ensure that all components work seamlessly together to prevent costly repairs. Always check for industry certifications on the products you choose.

When evaluating plastic pipe fittings, material properties are critical. Different plastics have varying chemical resistances.

Polyvinyl chloride (PVC) is common for water applications. Polypropylene (PP) offers better temperature resistance. Knowing the environment where the fittings will be used is essential.

Consider the pressure ratings of the materials. Not all fittings can handle high pressure. Some may degrade over time or under stressful conditions.

Check for certifications that indicate quality. This ensures the product meets safety standards. Often, people overlook these details and face issues later.

Maintenance requirements vary with materials. Some plastics can be more susceptible to UV light. Others may need specific cleaning methods to avoid degradation.

Reflect on how these factors influence your choice. A fitting that seems right today could become a problem in the future. Be mindful of how it impacts your entire plumbing system.

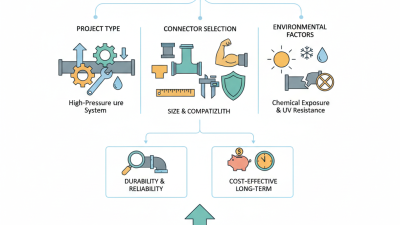

When choosing plastic pipe fittings, compatibility with existing plumbing systems is crucial. Every system has unique needs. The wrong fitting can lead to leaks or poor performance. Start by assessing the materials already in use. Whether it's PVC, CPVC, or another type, understanding your current setup is essential.

Check the diameter of the pipes. Mismatched sizes can create significant issues. Using fittings that are too large or too small might not seal properly. This can lead to a cascade of troubles, from minor leaks to major replacements. Also, consider the pressure ratings. Some fittings can't handle high pressure. Ignoring this factor may cause them to fail at critical moments.

It's also important to think about temperature ranges. Some plastic fittings aren't rated for high heat. If your plumbing has hot water flowing through it, ensure the materials can withstand the temperature. Don't overlook this detail. Even seemingly compatible materials might react poorly to fluctuating conditions. Always double-check compatibility before finalizing your decision. Taking time to assess these factors can save you money and stress in the long run.

| Tip Number | Tip Description | Compatibility Considerations | Common Applications |

|---|---|---|---|

| 1 | Assess the Pipe Material | Ensure fittings match pipe types (PVC, CPVC, etc.) | Residential plumbing, irrigation systems |

| 2 | Check Pressure Ratings | Verify that fittings can handle the system's pressure | Water supply, drainage |

| 3 | Evaluate Temperature Resistance | Use fittings suitable for temperature extremes | Hot water systems, HVAC |

| 4 | Select Proper Fitting Types | Choose between elbows, tees, couplings, etc. | Pipelines, construction projects |

| 5 | Consider Jointing Method | Assess whether solvent cement, threaded, or other methods | Diverse plumbing applications |

| 6 | Review Code Compliance | Ensure fittings meet local plumbing codes | Building constructions, renovations |

| 7 | Analyze Environmental Impact | Choose eco-friendly materials when possible | Sustainable projects, eco-plumbing |

| 8 | Determine Size Requirements | Select fittings that match pipe diameters | Home plumbing, industrial applications |

| 9 | Inspect for Quality Certifications | Look for NSF or other quality marks | Healthcare, food and beverage applications |

| 10 | Consult with Experts | Get advice from plumbing professionals when in doubt | Custom installs, troubleshooting |

When selecting plastic pipe fittings, size and specifications are crucial for a proper fit. It may seem simple, but many overlook measurements. A tiny error can lead to significant leaks or system failures. Each fitting has a specific diameter and pressure rating. Ensure you read the specifications carefully. Measure the existing pipes accurately to avoid mismatches.

In addition to size, consider the type of connections. Different systems may require unique fittings. Threads, couplings, and slip fittings all serve specific purposes. Sometimes, it’s tempting to make compromises. However, this can create more problems down the line. Reflect on the long-term implications of your choices. Proper fitting ensures a reliable and efficient system without unnecessary repairs.

Don’t forget to evaluate the surrounding conditions. Are temperatures and exposure factors suitable for the chosen material? This often gets neglected. Awareness of your environment can save time and money. Make thoughtful choices, and seek assistance if needed.

When choosing plastic pipe fittings, manufacturer reputation and product quality standards are crucial. A reliable manufacturer usually invests in rigorous quality assurance processes. According to industry reports, about 30% of plumbing issues stem from inferior fittings. This indicates that choosing low-quality products can lead to costly repairs and project delays.

Research potential suppliers. Look for manufacturers that adhere to established standards like ASTM or ISO. These certifications ensure products meet specific quality metrics. Check customer reviews and ratings. Positive feedback can indicate a company's reliability.

Tip: Always request product samples if possible. Testing a fitting beforehand can save time and money. Remember, even well-known brands can produce faulty items. So, it's wise to stay vigilant. The quality of the materials also impacts performance durability. A fitting might look good but might not withstand pressure or temperature changes effectively.

In some cases, suppliers may cut corners in production. This could lead to weak joints that compromise the entire system. Evaluating the source helps in avoiding these pitfalls. A careful assessment of the manufacturer can ensure you choose better quality fittings for your project.

Sign up for our mailing list to stay informed and up to date with our latest news and products!

(905) 832 – 0600

2175-A Teston Road

Maple, Ontario

L6A 1T3

(780) 451 – 0238

24790 – 117 Avenue

Acheson, Alberta

T7X 6C2

(604) 882 – 1564

9511 – 194A Street

Surrey, British Columbia

V4N 4G4

(306) 955 – 6005

3926 Arthur Rose Avenue Saskatoon, Saskatchewan

S7P 0C9

(450) 687 – 2721

2750 Rue Bernard-Lefebvre

Laval, Quebec

H7C 0A5