When it comes to home improvement projects, understanding the materials you work with is crucial for ensuring successful outcomes. Black PVC pipe, commonly used in a variety of plumbing and construction applications, offers a range of advantages such as durability, resistance to corrosion, and ease of installation. These pipes are especially popular for drainage systems, irrigation, and venting due to their ability to withstand harsh environmental conditions. However, working with black PVC pipe requires specific knowledge and techniques to maximize its benefits while minimizing potential challenges.

In this guide, we will provide you with ten essential tips for effectively working with black PVC pipe in your home projects. Whether you are a seasoned DIY enthusiast or a novice looking to undertake your first plumbing task, understanding these tips will enhance your skills and confidence. From selecting the right fittings to mastering cutting and joining techniques, each tip is designed to ensure that you achieve a secure and long-lasting installation. With the right approach, black PVC pipe can become a valuable asset in your home improvement endeavors.

Black PVC pipe, primarily known for its astute applications in drainage, waste, and vent systems, offers a variety of characteristics that make it a reliable choice for home improvement projects. Unlike its gray counterpart typically used for electrical conduits, black PVC is engineered for durability and resistance to harsh environmental factors. It is commonly composed of Polyvinyl Chloride (PVC), a material recognized for its excellent chemical resistance, making it suitable for transporting wastewater. According to the American Society for Testing and Materials (ASTM), black PVC pipe also exhibits low thermal conductivity, which helps prevent heat loss in plumbing systems.

In addition to its physical properties, working with black PVC pipe requires an understanding of its installation practices. Proper cutting and joining techniques are essential for ensuring leak-proof connections, often achieved through solvent cement that creates a robust bond. As noted in industry research, improper installation can lead to system failures, highlighting the importance of adhering to recommended guidelines and local building codes. Additionally, the National Association of Home Builders states that black PVC pipe can offer homeowners a cost-effective solution, with long-term performance benefits and minimal maintenance requirements, underscoring its viability for numerous plumbing applications.

| Tip | Description | Applications | Advantages |

|---|---|---|---|

| 1. Proper Cutting | Use a pipe cutter or saw to create clean, straight cuts. | Drainage systems, irrigation. | Ensures a secure fit when joining pipes. |

| 2. Deburring Edges | Remove any burrs from cut edges to prevent leaks. | Water supply lines, vent systems. | Improves joint integrity. |

| 3. Use Primer | Apply primer before cementing joints for better adhesion. | Sewage and drainage pipes. | Enhances the strength of the bond. |

| 4. Proper Adhesive | Choose the right type of PVC cement for your needs. | Piping in basements, underground installations. | Prevents future leaks and failures. |

| 5. Allow Drying Time | Allow adequate time for seams to cure before pressurizing. | Water lines, irrigation systems. | Reduces the chance of joint failure. |

| 6. Temperature Considerations | Be mindful of temperature changes as they can cause expansion. | Outdoor piping, extreme climates. | Prevents cracking and damage. |

| 7. Support Structures | Install appropriate supports to avoid sagging. | Horizontal piping systems. | Maintains alignment and flow. |

| 8. Regular Maintenance | Inspect regularly for signs of wear or damage. | Home plumbing, outdoor systems. | Prevents costly repairs. |

| 9. Know Local Codes | Ensure compliance with local plumbing codes. | All plumbing projects. | Avoids legal issues and ensures safety. |

| 10. Safety Gear | Always wear safety glasses and gloves during installation. | Any project involving cutting or adhesive. | Protects from injuries and chemical exposure. |

When working on home projects involving black PVC pipe, having the right tools is essential for achieving a successful outcome. Black PVC pipe, commonly known for its durability and resistance to corrosion, is frequently used in both plumbing and irrigation systems. According to the Plastics Pipe Institute, the use of PVC pipe in residential applications has increased by 10% over the last 5 years, highlighting its growing popularity. To effectively work with this material, you will need specific tools that ensure precision and efficiency.

Key tools include a pipe cutter, which allows for clean and straight cuts, minimizing the risk of leaks at joints. A deburring tool is also vital to smooth the edges after cutting, preventing damage to seals. Additionally, a heat gun can be indispensable for bending pipes when required by the layout of your project. For joining sections of black PVC pipe, a solvent cement application tool ensures an even distribution of adhesive, which is crucial for creating strong, leak-proof connections. Recent industry reports indicate that improper connections are the leading cause of plumbing failures, further underscoring the importance of using the right tools for your projects.

Equip yourself with these essentials, and you'll be well on your way to mastering black PVC pipe installations with ease and reliability.

When working with black PVC pipe, proper cutting and joining techniques are essential for achieving a durable and leak-free system. Start by assembling your tools: a pipe cutter or saw, measuring tape, a marker, and PVC primer and cement. Measure the length of the pipe you need and mark it clearly to ensure accuracy. If using a saw, make sure to cut slowly to avoid damaging the pipe's integrity, and always wear safety goggles to protect your eyes from debris.

Once you have your pipes cut to the desired lengths, the next step is to prepare the joints. Clean the surfaces that will be bonded by using a PVC cleaner to remove any dirt or grease. Apply the PVC primer to both the pipe and the fitting; this helps the cement bond properly. After priming, apply a generous amount of PVC cement to both surfaces, ensuring an even coating. Quickly push the pipe into the fitting, giving it a slight twist to ensure an even distribution of the cement. Hold the joint together for a few moments to allow the cement to set, and be sure to let it cure for the recommended time before exposing the pipes to water pressure. With these step-by-step instructions, you can confidently work with black PVC pipe for your home projects.

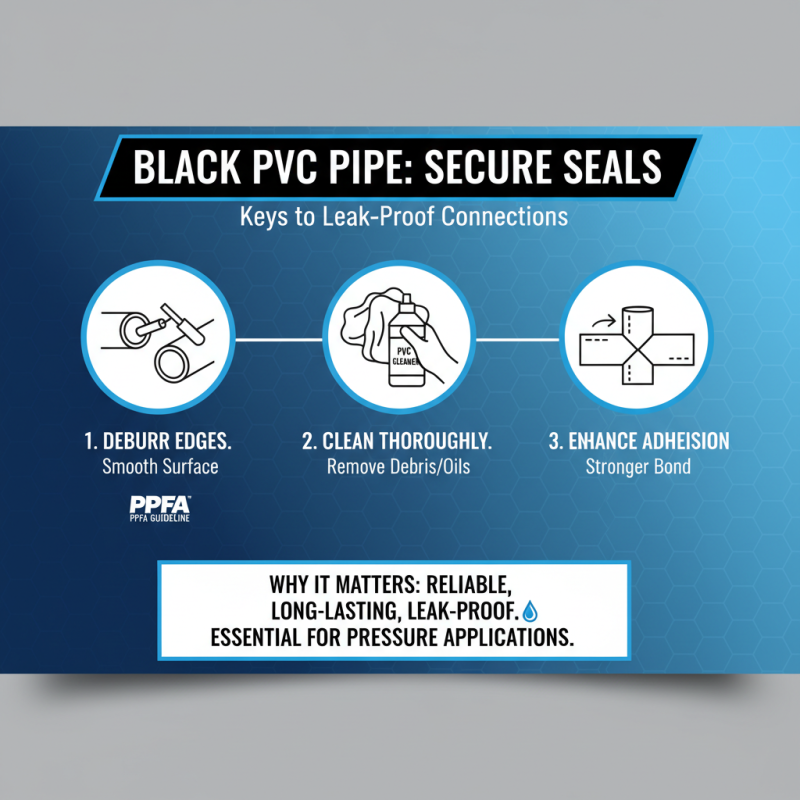

When working with black PVC pipe, ensuring a secure seal in connections is crucial to prevent leaks and maximize the longevity of your home projects. One of the key factors in achieving a reliable seal is the proper preparation of the pipe ends. According to the Plastic Pipe and Fittings Association (PPFA), a clean, smooth surface is essential for effective bonding. Deburring the edges and thoroughly cleaning the surfaces with a PVC cleaner can significantly enhance the adherence of the adhesive used. This small step can make a notable difference, particularly in pressure applications where the integrity of the seal is paramount.

Choosing the right adhesive is equally important. For black PVC pipe, a solvent cement specifically formulated for PVC should be used. Research indicates that using the correct type of solvent cement can improve bond strength by up to 20%, as stated in the ASPE Data Book. Additionally, while applying the cement, it's recommended to follow the instructions regarding the coating thickness and curing time. Often, allowing the joint to sit undisturbed for a minimum of 30 minutes before pressure testing can help ensure that the chemical reaction fully sets, thus providing a more reliable seal. Proper techniques not only lead to successful installations but also play a vital role in the overall functionality and safety of plumbing systems.

When working with black PVC pipe for home projects, avoiding common mistakes can significantly enhance both the efficiency and safety of your installations. One prevalent error is insufficient preparation before cutting, as improper cuts can lead to leaks and require additional fittings that complicate your system. According to a report by the American Society of Plumbing Engineers, approximately 20% of plumbing issues originate from improperly cut or fitted pipes. Taking the time to measure carefully and use the right tools can mitigate these risks.

Another frequent mistake is neglecting to account for expansion and contraction in the piping. Black PVC has a linear expansion coefficient that can lead to significant movement when the temperature fluctuates. Industry research indicates that a temperature change of just 10 degrees Fahrenheit can cause up to a quarter inch of movement per 10-foot length of pipe. Failing to sufficiently secure the pipes or allowing for this natural movement can result in stress points that may eventually lead to cracks or failures. Incorporating expansion joints and proper anchoring techniques can help address this issue, ensuring a durable and reliable plumbing system.

Sign up for our mailing list to stay informed and up to date with our latest news and products!

(905) 832 – 0600

2175-A Teston Road

Maple, Ontario

L6A 1T3

(780) 451 – 0238

24790 – 117 Avenue

Acheson, Alberta

T7X 6C2

(604) 882 – 1564

9511 – 194A Street

Surrey, British Columbia

V4N 4G4

(306) 955 – 6005

3926 Arthur Rose Avenue Saskatoon, Saskatchewan

S7P 0C9

(450) 687 – 2721

2750 Rue Bernard-Lefebvre

Laval, Quebec

H7C 0A5