In construction and plumbing, the choice of materials greatly impacts project longevity. Schedule 80 PVC pipe stands out due to its high pressure rating and durability. According to the Plastics Pipe Institute, PVC pipe usage has increased by over 25% in the last decade. This growth is largely attributed to its corrosion resistance and lightweight properties.

Using schedule 80 PVC pipe can lead to strong and reliable systems. Yet, many professionals overlook proper handling and installation methods. For example, cutting and joining techniques are often rushed, leading to leaks or stress fractures. Proper jointing and support can enhance the pipe's lifespan significantly.

While the advantages are clear, some remain cautious. Misconceptions about the pipe's capabilities can lead to suboptimal applications. It’s essential to reflect on past experiences and focus on best practices for installation. A well-planned approach ensures the maximum benefits of schedule 80 PVC pipe in your projects.

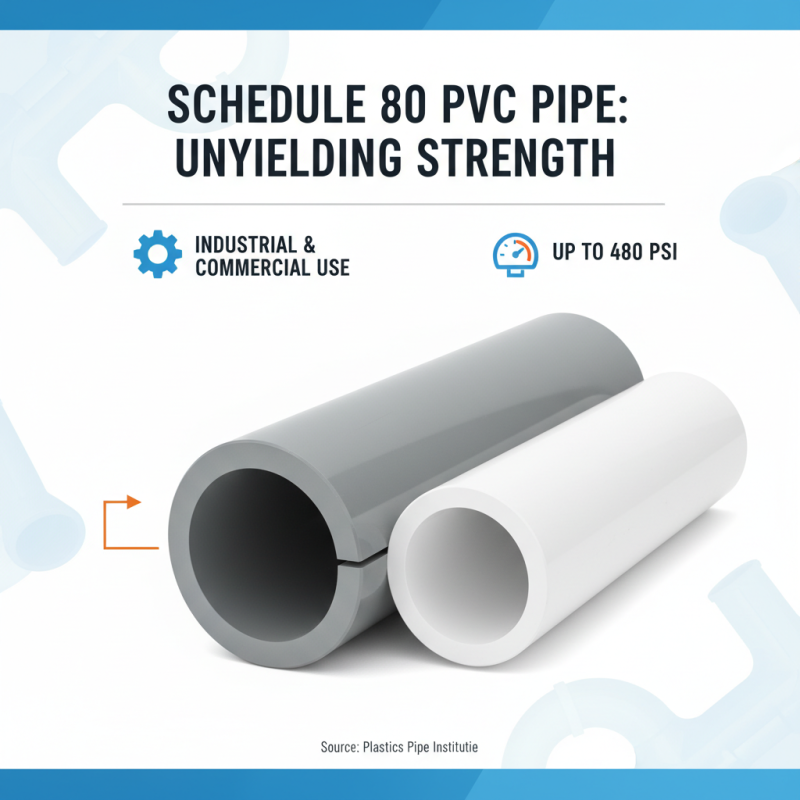

Schedule 80 PVC pipes are known for their durability and strength. They have a thicker wall compared to Schedule 40 pipes, making them suitable for higher pressure applications. According to the Plastics Pipe Institute, Schedule 80 pipes can handle pressures up to 480 psi, depending on the diameter and temperature. This makes them ideal for industrial and commercial environments.

Applications range from chemical processing to water treatment. The chemical resistance of PVC makes it a common choice for transporting aggressive fluids. In fact, a study by the American Society for Testing and Materials found that Schedule 80 PVC maintains structural integrity in harsh conditions better than many metals. However, one must also consider the impact of UV light on long-term exposure. Inadequate protection can lead to degradation over time.

When using Schedule 80 PVC, proper installation is crucial. Misalignment or improper fittings can cause leaks or failure under pressure. A report by the National Joint Pipe Jacking Association highlights the importance of adhering to installation guidelines. Many projects overlook this detail, leading to costly repairs. Understanding how to correctly use Schedule 80 PVC can significantly enhance the longevity and safety of your plumbing systems.

Schedule 80 PVC pipe stands out in many projects due to its strength and durability. This type of pipe features thicker walls compared to standard PVC. As a result, it is better equipped to handle high pressure. For applications like water supply and chemical transportation, this is crucial. The added thickness helps prevent cracking, ensuring long-term reliability.

Another key advantage is its resistance to corrosion. Unlike metal pipes, Schedule 80 PVC does not rust or degrade over time. This property makes it ideal for outdoor projects and installations in humid environments. Additionally, it is lightweight, which simplifies transportation and installation. Working with this material can be easier for DIY enthusiasts.

However, using Schedule 80 PVC requires careful consideration. It can be more expensive than other options. Some may find it challenging to cut and work with, especially if they lack proper tools. Misjudging the necessary pipe size or connector types can lead to project delays. Understanding these factors can help you avoid potential pitfalls and make the best use of this valuable material.

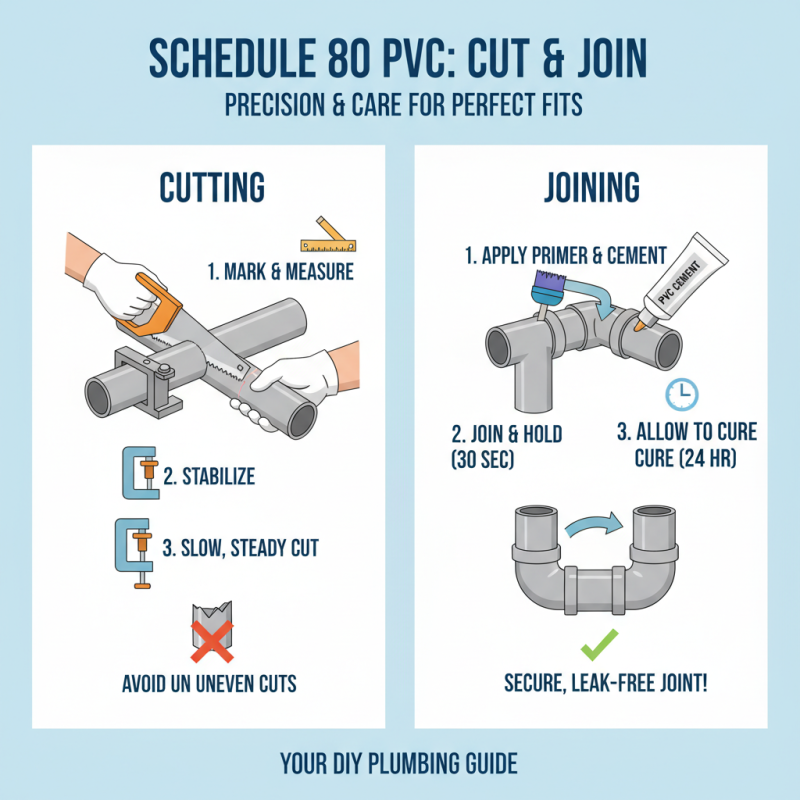

Cutting and joining Schedule 80 PVC pipe requires attention and precision. First, gather the proper tools: a fine-toothed saw and a deburring tool. Mark your cut with a pencil. Ensure your measurement is accurate. An incorrect cut can waste material. Use clamps to stabilize the pipe. This helps keep it steady while you cut. Remember to cut slowly. Uneven cuts will complicate the joining process.

Once you have your pieces, it’s time for joining. Clean the ends of the pipes thoroughly. Any dirt can lead to poor adhesion. Remember to apply the solvent to both the pipe and the fitting. A common mistake is applying too little. This can weaken the joint. Hold the pieces together for a few seconds to allow the solvent to set. It’s crucial to follow the specified curing time for maximum strength.

Take a moment to reflect on your process. Did you take enough care in cutting? Did you ensure cleanliness? These factors affect the durability of your project. Even experienced DIYers sometimes overlook details. Adjust your approach as needed in future projects for improved results.

Proper installation techniques are crucial for maximizing the durability and effectiveness of Schedule 80 PVC pipe systems. This type of pipe is designed for high-pressure applications, making it essential to follow specific guidelines during installation. According to industry data, Schedule 80 PVC can withstand pressures up to 480 psi, but improper installation can compromise these capabilities.

Ensure pipe ends are cut cleanly and squarely. A good cut allows for better fitting and a stronger bond. Deburr the edges to remove any sharp bits. This prevents stress points that can lead to failure. When joining pipes, use the right solvent cement. Manufacturers often stress the importance of allowing adequate curing time for the cement. It’s easy to overlook, but rushing this step can weaken the joints.

Tip: Always conduct a pressure test on your system after installation. A leak can signal that joints aren’t secure. Also, be mindful of the temperature fluctuations that Schedule 80 may face. PVC can become brittle under extreme conditions. Adequate insulation can mitigate these issues. Pay attention to your environment during installation; it may save you from future headaches.

| Installation Technique | Description | Benefits | Common Applications |

|---|---|---|---|

| Cutting | Use a saw designed for PVC to ensure clean cuts without burrs. | Ensures better joint integrity and prevents leaks. | Water supply lines, drainage, and electrical conduit. |

| Deburring | Remove any excess plastic from the cut ends to facilitate smoother joining. | Prevents damage to O-rings and improves sealing. | Plumbing systems and industrial applications. |

| Priming | Apply PVC primer to joints to enhance adhesive bonding. | Improves joint strength and prevents potential leaks. | Sewage and vent pipes. |

| Gluing | Use PVC cement to bond pieces together after priming. | Creates a permanent and waterproof seal. | Irrigation systems and chemical transport. |

| Support and Alignment | Ensure pipes are properly supported to prevent sagging or stress. | Extends the life of the piping system and reduces failures. | Construction of infrastructure and building services. |

Schedule 80 PVC pipe is a durable option for various projects. However, proper maintenance is crucial for its longevity. Regular inspections can help identify cracks or damage. Cleaning the surface occasionally prevents buildup and discoloration.

One key tip for maintaining Schedule 80 PVC is to protect it from ultraviolet light. Sunlight can degrade the material over time. If it's exposed to the elements, consider using protective covers. Another tip is to avoid extreme temperature changes. Rapid fluctuations can stress the pipe, leading to failures.

Ensure that joints are properly sealed. Leaky joints can cause problems down the line. Over-tightening can also lead to cracks. So, find the right balance during installation. A little extra care can go a long way. Remember, a small oversight now may result in bigger issues later.

Sign up for our mailing list to stay informed and up to date with our latest news and products!

(905) 832 – 0600

2175-A Teston Road

Maple, Ontario

L6A 1T3

(780) 451 – 0238

24790 – 117 Avenue

Acheson, Alberta

T7X 6C2

(604) 882 – 1564

9511 – 194A Street

Surrey, British Columbia

V4N 4G4

(306) 955 – 6005

3926 Arthur Rose Avenue Saskatoon, Saskatchewan

S7P 0C9

(450) 687 – 2721

2750 Rue Bernard-Lefebvre

Laval, Quebec

H7C 0A5