As industries continue to seek advanced materials for their piping systems, Polyvinylidene Fluoride (PVDF) pipe emerges as a leading choice for 2025 projects. Renowned for its exceptional chemical resistance and high-temperature tolerance, PVDF pipe is particularly suited for demanding environments, making it a preferred solution in sectors such as chemical processing, food and beverage, and pharmaceuticals. According to a recent report by the Global Plastics Industry, the demand for PVDF materials in piping applications is projected to grow by over 15% annually until 2025, underscoring its critical role in future projects.

Expert insights further highlight the advantages of PVDF pipes. Dr. Emily Carter, a leading analyst in the polymer science field, states, “The resilience and versatility of PVDF pipes are unmatched, providing engineers and project managers with the reliability needed for high-performance applications.” With its ability to withstand harsh chemicals and extreme temperatures, PVDF pipe stands out as an ideal alternative to traditional materials, ensuring safety and durability across various sectors. As we approach 2025, understanding the compelling reasons to opt for PVDF pipe will be crucial for professionals aiming to enhance their operational efficiency and project outcomes.

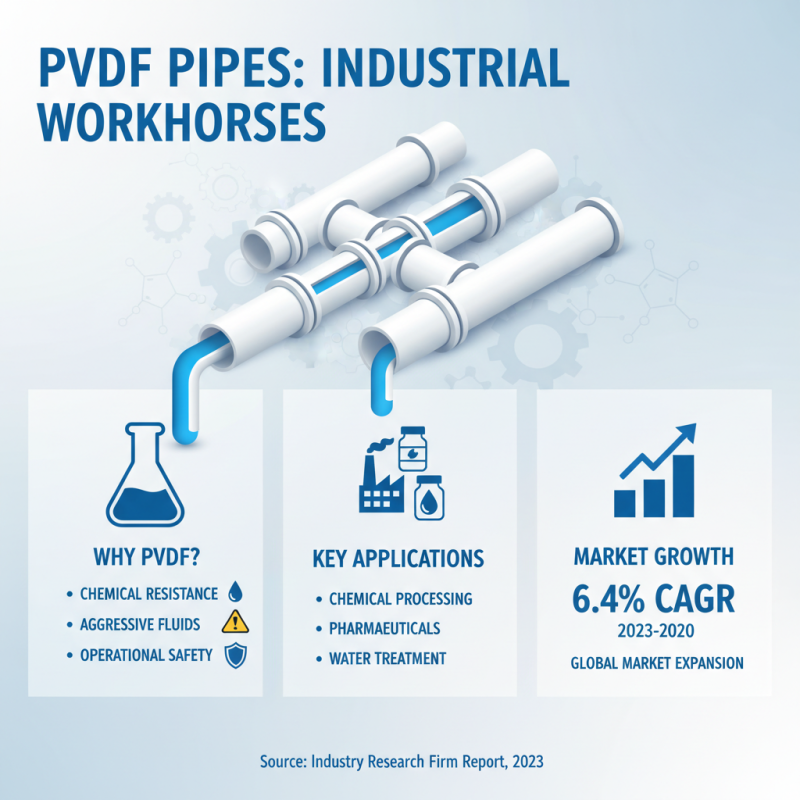

Polyvinylidene fluoride (PVDF) pipes have become increasingly prominent in industrial applications due to their exceptional performance characteristics. One of the primary advantages of PVDF is its excellent chemical resistance, making it suitable for transporting aggressive fluids in sectors such as chemical processing, pharmaceuticals, and water treatment. According to a report from a leading industry research firm, the global market for PVDF materials is expected to witness a compound annual growth rate (CAGR) of 6.4% from 2023 to 2030, demonstrating the rising demand for high-performance piping solutions. This chemical inertness ensures that the integrity of the transported substances remains uncompromised, further improving operational safety.

Another critical factor contributing to the popularity of PVDF pipes is their superior thermal stability, which can tolerate temperatures ranging from -40°C to +150°C. This characteristic is particularly vital for industries that require stringent temperature controls, such as automotive and food processing. Additionally, PVDF's lightweight nature and easy installation properties reduce labor costs and time, as highlighted in a recent analysis from the American Society of Civil Engineers, which indicates that the implementation of PVDF can significantly lower the total costs associated with piping systems by up to 20%. These advantages collectively position PVDF pipes as a top choice for upcoming projects focused on sustainability and efficiency in industrial applications.

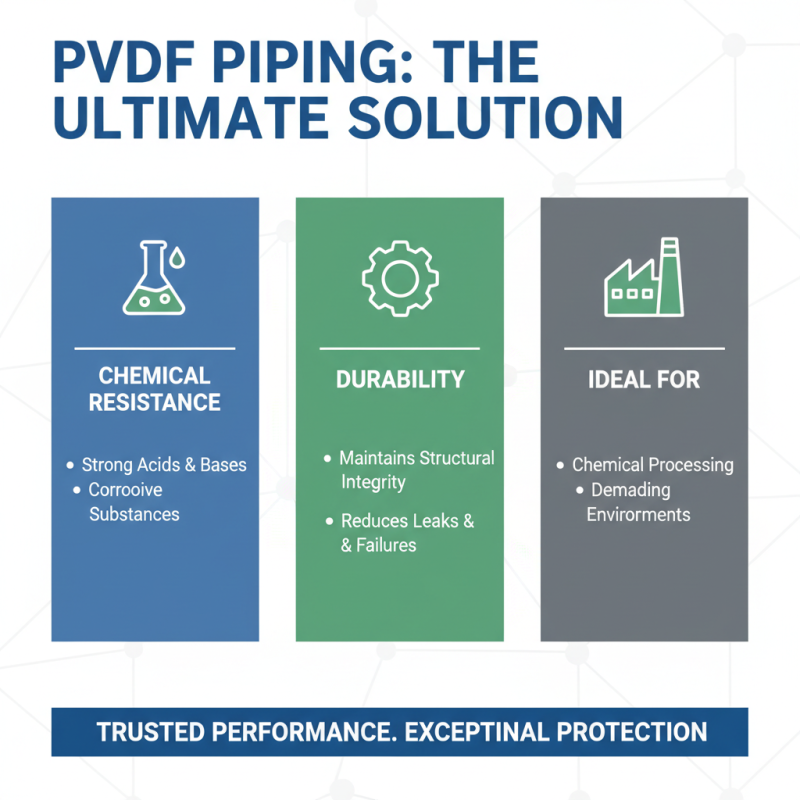

PVDF (Polyvinylidene Fluoride) has emerged as a premier choice for piping solutions, particularly in demanding environmental conditions due to its exceptional chemical resistance and durability. According to a report published by the Chemical Resistance of Plastics Standards, PVDF exhibits outstanding resistance to a wide range of chemicals, including strong acids and bases, making it ideal for use in the chemical processing industry. The material retains its structural integrity and performance even when exposed to harsh corrosive substances, which significantly reduces the risk of leaks and failures in your piping systems.

In addition to its chemical resistance, PVDF also boasts remarkable durability characteristics. Due to its high tensile strength and outstanding thermal stability, PVDF pipes can withstand extreme temperatures ranging from -60°C to 150°C, providing flexibility for various industrial applications. The material’s outstanding performance under both pressure and high flow rates is corroborated by the American Society for Testing and Materials (ASTM), which highlights its ability to meet rigorous safety and reliability standards. As industries increasingly prioritize sustainability and efficiency, choosing PVDF piping not only ensures longevity and lower maintenance costs but also aligns with environmental goals by minimizing the risk of hazardous spills.

When considering materials for long-term projects in 2025, one of the standout choices is PVDF (Polyvinylidene fluoride) pipe due to its remarkable cost-effectiveness. According to a report from the American Society of Mechanical Engineers, PVDF has been shown to provide significant savings in maintenance costs over its lifespan, often cited as up to 30% lower in comparison to traditional materials like metal or PVC. This is particularly important in industries such as chemical processing and water treatment, where the resilience and corrosion resistance of PVDF minimize frequent replacements and repairs, translating to tangible financial benefits.

Moreover, the longevity of PVDF pipes further enhances their cost-effectiveness. Industry research indicates that the average lifespan of PVDF pipes can exceed 50 years, making them a wise investment for projects with long-term operational needs. This durability not only reduces the frequency of installations and associated labor costs but also means fewer disruptions to operations. With the rise of sustainable practices, choosing materials that reduce waste—such as PVDF—aligns with corporate social responsibility goals, while improving the bottom line. By opting for PVDF pipes, project managers can ensure a balance of performance, longevity, and cost-efficiency, making them an ideal choice for 2025 and beyond.

This chart illustrates the cost-effectiveness of PVDF pipes compared to traditional materials over a span of five years for various project types. The values represent estimated costs in USD per meter of pipe, including installation and maintenance.

PVDF (polyvinylidene fluoride) pipes offer significant environmental advantages that make them a compelling choice for construction projects in 2025. First and foremost, PVDF is highly resistant to corrosive chemicals, which minimizes the risk of chemical leaching into the environment. This characteristic not only extends the lifespan of the piping system but also reduces the ecological footprint associated with frequent replacements and repairs. Additionally, PVDF's inert nature means it does not react negatively with substances that may be transported through the pipes, further safeguarding groundwater and nearby ecosystems.

Moreover, the production process of PVDF is designed to be energy-efficient, resulting in lower carbon emissions compared to other piping materials. Utilizing PVDF can contribute to meeting sustainability goals, as it is often manufactured with a focus on reducing resource consumption. The durability of PVDF against environmental stressors like UV radiation and extreme temperatures also ensures that it remains functional over a long period, diminishing the need for replacement and thereby decreasing waste. As construction continues to evolve towards more eco-friendly practices, the integration of materials like PVDF aligns perfectly with the global drive for sustainability.

| Feature | Description | Environmental Benefit |

|---|---|---|

| Chemical Resistance | PVDF pipes resist a wide range of chemicals, reducing risk of leaks and spills. | Minimizes soil and water contamination, contributing to environmental preservation. |

| Durability | High strength and long lifespan make PVDF pipes less prone to damage. | Reduces waste generation from repairs and replacements, promoting sustainability. |

| Lightweight | Easier handling and installation due to low weight. | Lower transport emissions and reduced energy usage in construction. |

| Thermal Properties | High thermal resistance maintains integrity in varying temperatures. | Reduces energy usage of heating/cooling systems. |

| Recyclability | PVDF can be recycled, making it easier to incorporate back into the production cycle. | Promotes circular economy and reduces landfill waste. |

PVDF (Polyvinylidene fluoride) pipe technology is at the forefront of innovation as we advance towards 2025. One of the most significant trends is the development of enhanced processing methods that improve the mechanical properties and durability of PVDF pipes. As manufacturers continue to refine their techniques, we can expect pipes that not only resist corrosion and chemicals but also offer superior resistance to temperature fluctuations, making them ideal for a variety of applications in harsh environments.

Another exciting trend is the integration of smart technology into PVDF pipes. These innovations enable real-time monitoring of flow rates, pressure, and even the structural integrity of the pipes. By utilizing IoT (Internet of Things) capabilities, operators can receive alerts about potential failures before they occur, minimizing downtime and maintenance costs. Such proactive management significantly enhances operational efficiency and safety in industrial settings.

Tips: When considering PVDF pipes for your projects, ensure that you assess the specific requirements of your application. Evaluate factors such as chemical compatibility, temperature ranges, and installation methods. Additionally, staying informed about the latest technological advancements will help you choose the most efficient and durable pipe solutions available, keeping your projects ahead of the curve.

Sign up for our mailing list to stay informed and up to date with our latest news and products!

(905) 832 – 0600

2175-A Teston Road

Maple, Ontario

L6A 1T3

(780) 451 – 0238

24790 – 117 Avenue

Acheson, Alberta

T7X 6C2

(604) 882 – 1564

9511 – 194A Street

Surrey, British Columbia

V4N 4G4

(306) 955 – 6005

3926 Arthur Rose Avenue Saskatoon, Saskatchewan

S7P 0C9

(450) 687 – 2721

2750 Rue Bernard-Lefebvre

Laval, Quebec

H7C 0A5