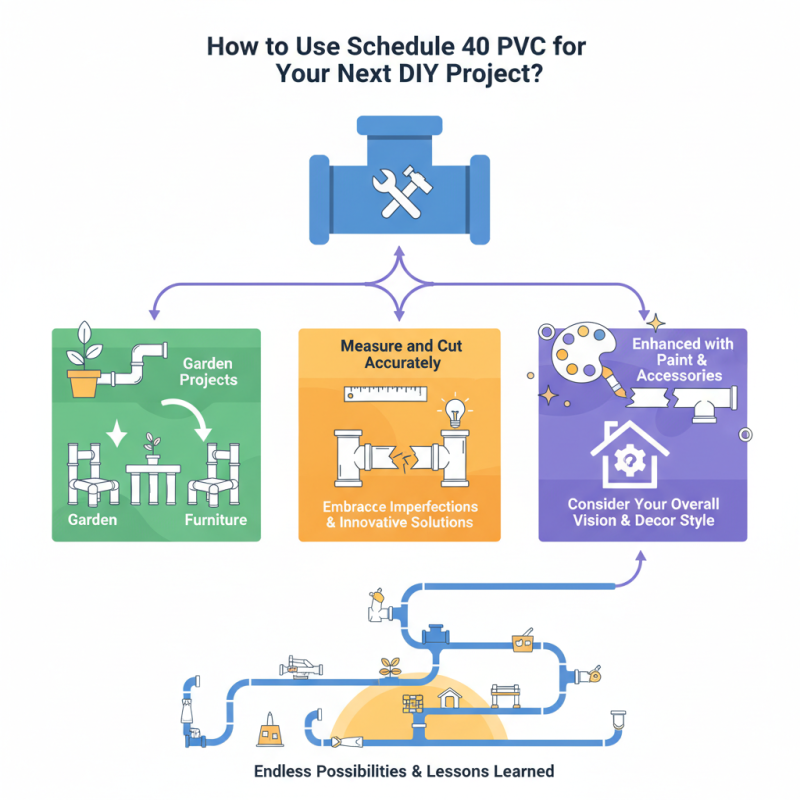

If you’re considering a DIY project, schedule 40 PVC can be an excellent choice. This material is widely used in plumbing and construction. However, its versatility extends far beyond these applications. From garden projects to furniture, schedule 40 PVC can be crafted into various useful items.

Using schedule 40 PVC might feel overwhelming at first. It has unique properties that require careful handling. You must measure and cut accurately. If you make a mistake, the project can lose its integrity. Yet, these small challenges can be part of the learning process. Embracing imperfections can lead to innovative solutions.

Moreover, the aesthetic appeal of schedule 40 PVC can be enhanced with paint and accessories. With some creativity, you can transform plain pipes into eye-catching designs. This material offers durability, but it may not fit every decor style. Consider your overall vision before diving in. The possibilities are endless, but so are the lessons learned along the way.

Schedule 40 PVC is a popular choice for many DIY projects. It is lightweight and easy to handle. The material is also resistant to corrosion, which is a significant advantage for outdoor use. These properties make it suitable for a range of applications. You can use it for plumbing, drainage, and even crafting.

In terms of durability, Schedule 40 PVC can withstand high pressure, making it ideal for water systems. However, it can become brittle in very cold weather. You might want to consider heat exposure when planning your project. Cutting the pipes requires a bit of precision. Make sure your measurements are accurate; mistakes can lead to wastage.

When connecting pieces, using the correct adhesive is crucial. Not all adhesives work well with PVC. If you're not careful, joints may not hold, leading to leaks. Experiment with different techniques to find what works best for you. It’s all part of the learning process in DIY projects.

When embarking on a DIY project with Schedule 40 PVC, the right tools and materials are crucial. You'll need a tape measure to ensure accurate cuts. A saw designed for plastic will help create clean edges. Don’t forget to wear safety goggles; cutting PVC can send small pieces flying. A marker or pencil is handy for marking your cutting lines.

For assembly, PVC cement is essential. This adhesive bonds the pipes securely. Consider a pipe cleaning solution to prepare the surfaces. Use a level to check your work, ensuring everything is straight. It may take several tries to get your measurements right. Patience is key.

If you’re working on a project like a garden irrigation system, gather fittings and connectors. These pieces help shape your design. You might find yourself going back to the hardware store for more. It’s normal to underestimate what you need. Planning can help, but flexibility is vital in DIY. Each project teaches you something new, often about your own process.

Cutting and joining Schedule 40 PVC pipes can seem daunting, but with the right techniques, it becomes manageable. Begin by evaluating the length you need for your project. Accurate measurements are crucial. In the U.S., about 75% of DIY projects rely on PVC for plumbing and construction due to its durability and cost-effectiveness. Grab a good-quality PVC cutter or a hacksaw. Ensure you make straight, clean cuts. Rough edges can cause leaks when you join the pipes.

When it comes to joining the pipes, proper adhesive application is key. Use solvent cement specifically for PVC. Apply it evenly on both the pipe and the fitting. Push them together, and hold firmly for about 30 seconds. In a recent industry report, more than 40% of failures in PVC joints were attributed to improper fitting. Allow the adhesive to cure fully before testing. Seemingly minor mistakes can lead to significant issues, so attention to detail is essential. If you notice any unexpected cracks or leaks, reflect on your process. Consider what you might adjust next time to improve your results.

Schedule 40 PVC is incredibly versatile for various DIY projects. Take a moment to imagine a simple but functional garden trellis. With just a few cuts and connectors, you can create a sturdy frame for climbing plants. This project requires minimal tools, making it accessible to anyone. However, you might face some challenges. Measuring inaccurately could lead to gaps in the structure. Remember, precision is key.

Another idea is building a DIY shoe rack. Using PVC pipes, you can design adjustable shelves that fit your space. The lightweight material allows easy rearrangement. You can paint the pipes to match your home decor, giving a personal touch. But beware: if not secured properly, the structure may wobble. Testing the stability after assembly is crucial.

Creating a network of organizers for cords and cables is another creative use. Simply cut the pipes into small lengths and attach them to a board. This not only declutters but also enhances the aesthetics of your workspace. Yet, think about the placement. If positioned carelessly, it could become a dust collector. Just like any project, reflection on flaws enhances your future creations.

When embarking on a DIY project using Schedule 40 PVC, safety should be your top priority. PVC is a versatile material, but it requires careful handling. According to a report by the American Society for Testing and Materials, improper use can lead to physical injuries. Always wear safety goggles and gloves to protect yourself from sharp edges and chemical exposure.

Tip: Always cut PVC in a well-ventilated area. The dust generated during cutting can be irritating. A mask can help minimize inhalation.

Ensure that your workspace is organized. Clutter can lead to accidents. According to the National Safety Council, a tidy workspace reduces the risk of injury by nearly 30%. Keep your tools within easy reach but secure to avoid tripping hazards. Remember, rushing through a project often leads to mistakes. Take your time to ensure every cut and joint is clean.

Tip: Before starting, sketch your project. Visualization helps catch potential problems before they arise. Reflect on your design and adjust as needed to prevent costly mistakes. Safety is not just about gear; it's about how you plan and execute your project.

Sign up for our mailing list to stay informed and up to date with our latest news and products!

(905) 832 – 0600

2175-A Teston Road

Maple, Ontario

L6A 1T3

(780) 451 – 0238

24790 – 117 Avenue

Acheson, Alberta

T7X 6C2

(604) 882 – 1564

9511 – 194A Street

Surrey, British Columbia

V4N 4G4

(306) 955 – 6005

3926 Arthur Rose Avenue Saskatoon, Saskatchewan

S7P 0C9

(450) 687 – 2721

2750 Rue Bernard-Lefebvre

Laval, Quebec

H7C 0A5